The Advantages of IQF Frozen Avocados

Individual Quick Frozen (IQF) avocados began to gain its popularity as the consumption of fresh avocados rises. However, fresh but over-ripe or odd-sized avocados are often rejected, which can be a big waste for both wholesales and consumers. Shelf life for fresh avocados is only 1~2 days; there is a high chance that avocados already overripe or even gone bad the day of purchase. An alternative is to buy underripe avocados at a high price and let it ripe at home. But knowing when an avocado is ripe for consumption is tricky, very often we end up finding an unappetizing discolored fruit with flavor changed.

IQF Frozen Avocado Customer Advantages

Shelf life for IQF frozen avocado is over 6 months. IQF frozen avocado is frozen at its peak of ripeness, then packed and sold in consumer bags or boxes. Food safety controls are done before dispatching. Transportation is convenient and safe. During the period of transportation, only Cold Chain needs to be controlled. IQF frozen avocados are available all year around whenever needed.

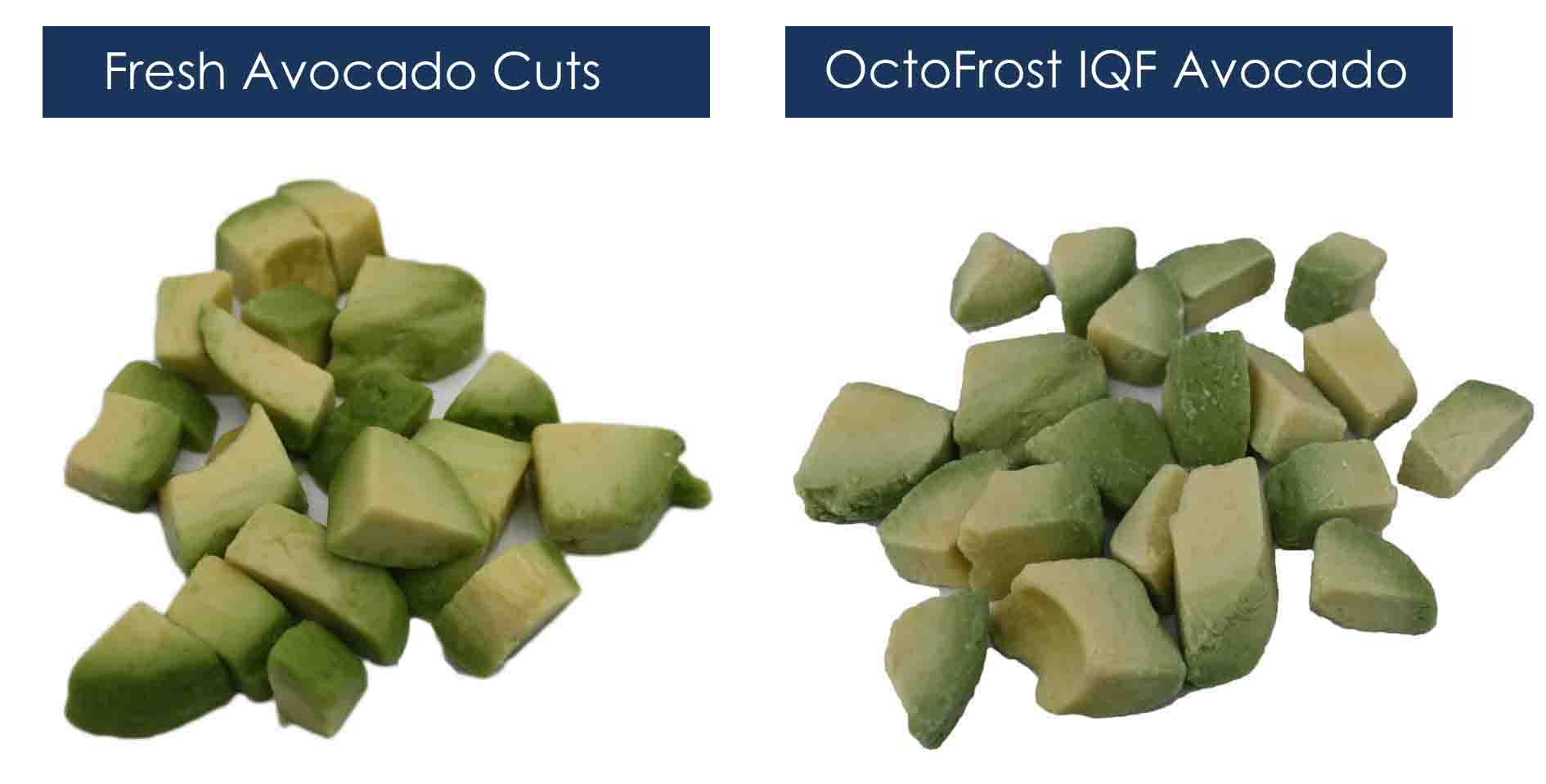

With OctoFrost’s IQF technology, it is possible to freeze just-right-to-eat avocados after harvesting, to ensure its natural appearance, texture, smell, and nutrients preserved. Therefore, consumers get to enjoy a quality fruit that’s full of flavor. IQF frozen avocados are often cut and frozen in halves, dices, or slices. It is convenient to pick the needed amount before thawing. This way we avoid food waste and especially bacteria growth which is caused by repeatedly thawing and freezing food that cannot be finished at once. We recommend thawing frozen avocado in the fridge.

Production Process

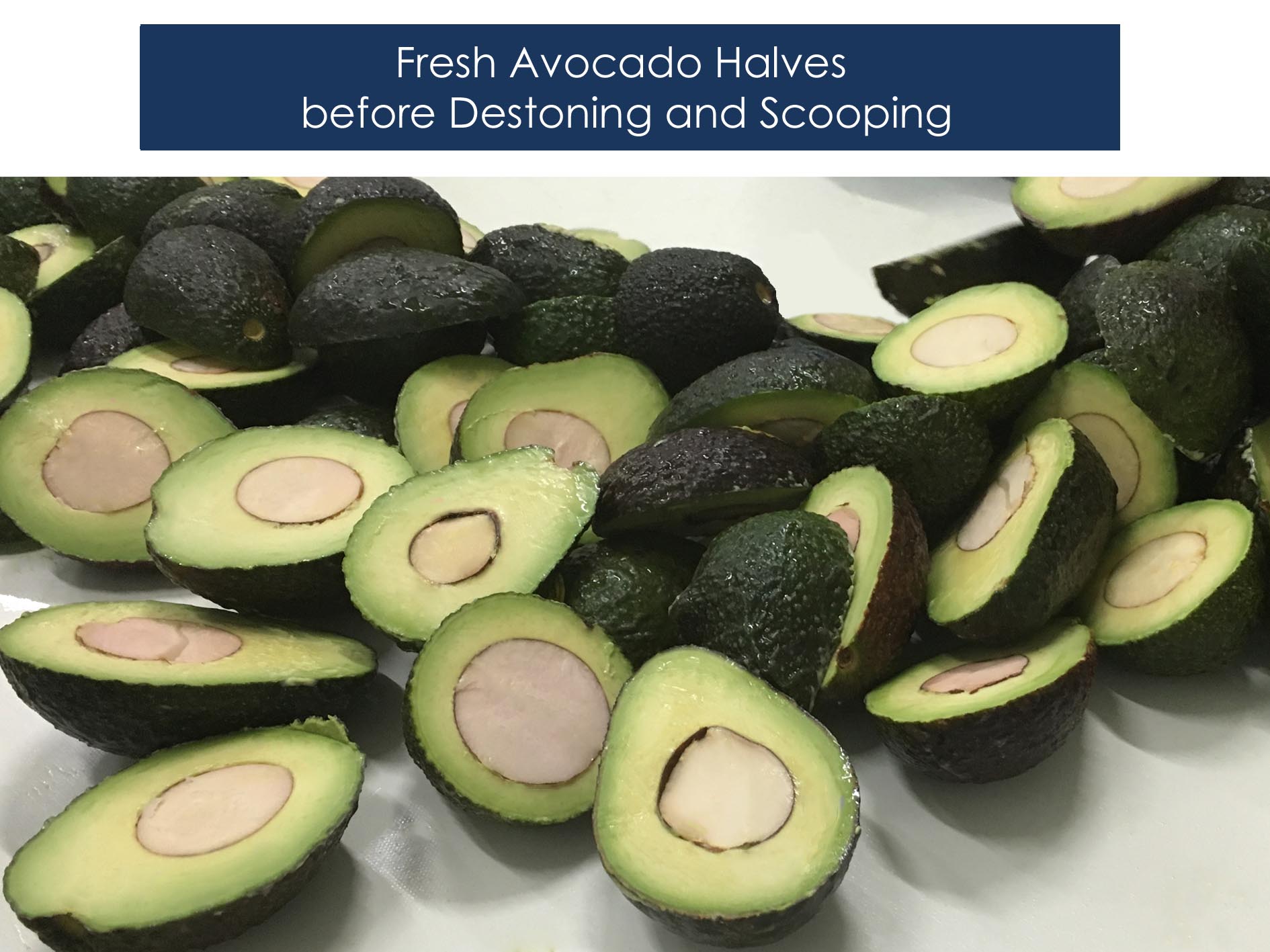

Cutting a whole avocado with a mechanical cutter is the first step before starting the processing process.  Having a low product temperature before cutting is essential, because it leads to a better product appearance. The ice-cold water in the OctoFrost™ Chillers cools the core temperature of avocados to less than 5 ° C for an even cut and an effective IQF freezing. Depending on your yearly production rate, OctoFrost™ can provide solutions for both small and large productions. Avocados are normally cut into two pieces with a cutter, and then destoned. Fruit meat is scooped out before dicing, cutting or segmenting. Some volumes are sold in halves. OctoFrost™ offers unique features to maintain a good product separation and its characteristics without any damages, for avocado halves and even sticky dices or slices. The cost per kg is usually lower with our new technology, and the yield is higher than other technologies on the market.

Having a low product temperature before cutting is essential, because it leads to a better product appearance. The ice-cold water in the OctoFrost™ Chillers cools the core temperature of avocados to less than 5 ° C for an even cut and an effective IQF freezing. Depending on your yearly production rate, OctoFrost™ can provide solutions for both small and large productions. Avocados are normally cut into two pieces with a cutter, and then destoned. Fruit meat is scooped out before dicing, cutting or segmenting. Some volumes are sold in halves. OctoFrost™ offers unique features to maintain a good product separation and its characteristics without any damages, for avocado halves and even sticky dices or slices. The cost per kg is usually lower with our new technology, and the yield is higher than other technologies on the market.  Processors in the Americas, Africa, and Asia have already experienced the benefits of these features that contribute to high yield and food safety.

Processors in the Americas, Africa, and Asia have already experienced the benefits of these features that contribute to high yield and food safety.